Published:11.12.2025

See moreDehumidifier Installation in Metal Component Manufacturing

Published:

11/10/2024, 16:32

- Updated at 30/09/2025, 09:43

Published:

11/10/2024, 16:32

- Updated at 30/09/2025, 09:43Humidity plays an important role in maintaining the quality and efficiency of metal component production. When humidity levels are too high, metals can easily oxidize, leading to corrosion and reduced durability. On the other hand, good humidity control allows for more precise machining, ensuring that coatings adhere securely and dry quickly, preventing peeling. Therefore, maintaining proper humidity is a key factor in ensuring product quality and production efficiency in the metal industry.

Installation Information

Recently, Kosmen Corporation has installed dehumidifiers to control humidity during metal component production. The details of the project are as follows:

- Purchaser: HB tech Trading Industrial company Limited

- Purpose: To control air humidity, ensuring optimal environmental conditions for production and product storage.

- Installation: Kosmen KM-480S dehumidifier.

Benefits of Using Kosmen Dehumidifiers

When applied to metal component production, Kosmen dehumidifiers have provided several practical benefits, including:

- Protecting metal surfaces from oxidation and corrosion, maintaining product quality and durability.

- Supporting more accurate metal processing, reducing deviations and ensuring products meet high standards.

- Helping coatings or finishes adhere more firmly and dry faster, minimizing the risk of blistering or peeling, and improving the aesthetic and durability of products.

- Protecting production equipment from damage due to mold and moisture, reducing maintenance costs and extending the lifespan of machinery.

- Kosmen dehumidifiers operate reliably and are energy-efficient, optimizing production costs and increasing overall productivity.

Customer Feedback

After implementing the Kosmen KM-480S industrial dehumidifier, HB Tech has reported significant improvements in the metal component production process. Optimal humidity control has not only effectively prevented metal oxidation and corrosion but also contributed to improving the quality and durability of the products.

Thanks to this stability, metal machining at HB Tech has become more precise, reducing unwanted deviations. In addition, the painting and coating processes have become smoother, with the coatings adhering more firmly and drying faster, minimizing the risk of peeling or blistering.

HB Tech also appreciates the protection that the dehumidifier provides for production equipment, safeguarding against damage caused by humidity, thereby reducing maintenance costs and extending machinery lifespan. Thanks to these benefits, the use of the Kosmen KM-480S dehumidifier has significantly enhanced HB Tech's production efficiency and product quality.

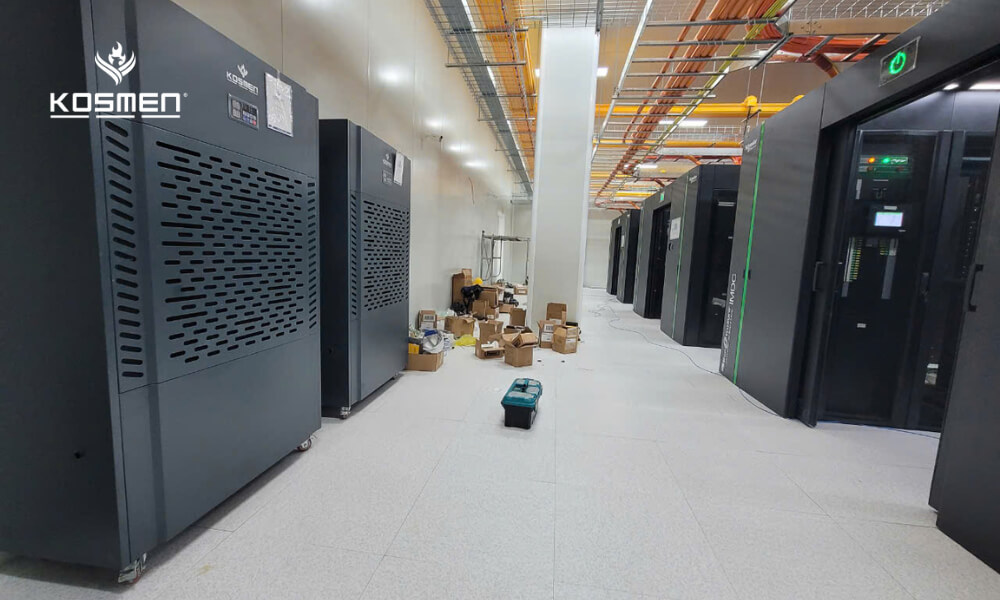

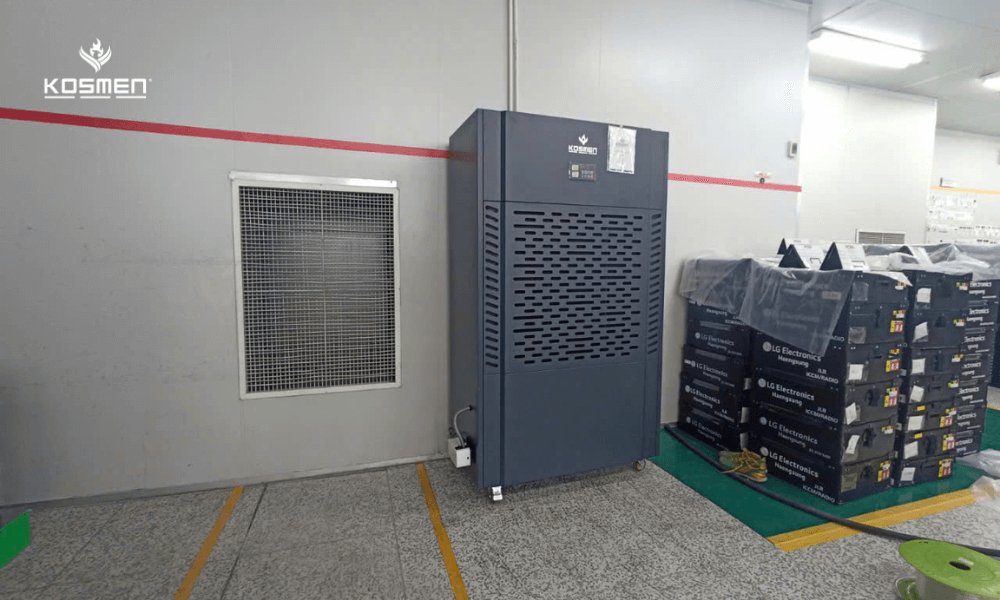

Below are some images of the industrial dehumidifier at HB tech Trading Industrial company Limited:

The Kosmen KM-480S industrial dehumidifier delivers efficient humidity control with superior multifunctionality

The Kosmen KM-480S protects products from damage and rust in metal component manufacturing

Its application ensures optimal humidity control in the metal production industry

With a high dehumidification capacity of up to 480 liters per day, the Kosmen KM-480S is ideal for large warehouses, storage areas, and factories