Published:11.12.2025

See moreDehumidifier For Preserving Artificial Ceramic Tile Press Machines

Published:

25/03/2025, 10:14

- Updated at 25/06/2025, 11:45

Published:

25/03/2025, 10:14

- Updated at 25/06/2025, 11:45In the artificial ceramic tile manufacturing industry, humidity is a factor that directly affects the quality of the final product as well as the lifespan of machinery. High humidity can cause tile powder to absorb water, altering the properties of the materials, affecting the pressing process, and reducing the durability of the tiles. Additionally, a humid environment can cause the metal parts in the press machine to rust and wear out, increasing maintenance and repair costs. To address this issue, many manufacturers have chosen Kosmen dehumidifiers – an optimal humidity control solution that helps protect equipment and improve product quality.

Project Details

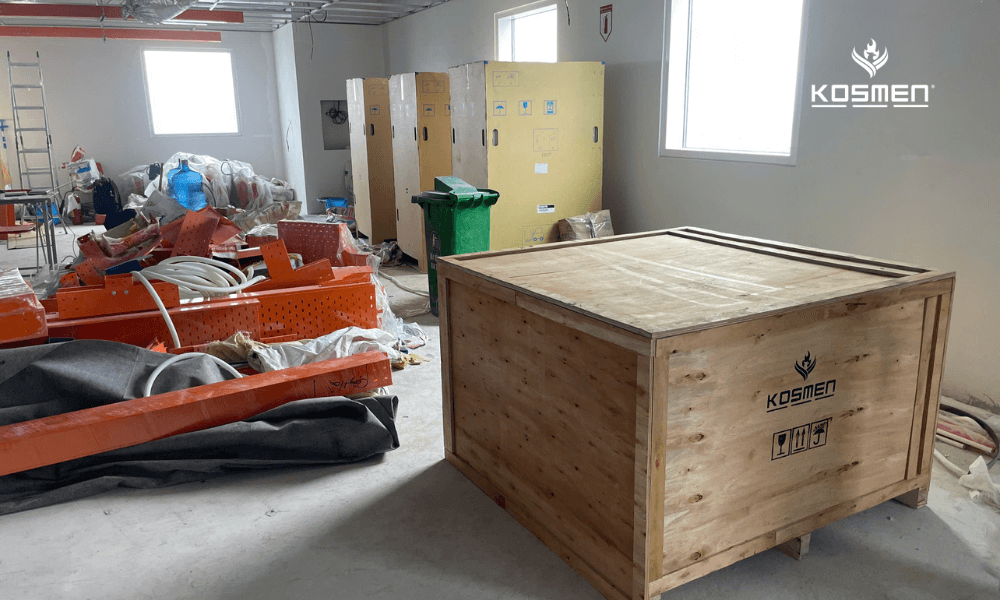

Recently, Kosmen installed an industrial dehumidifier system for an artificial ceramic tile manufacturing plant to control humidity, protect press machines, and enhance operational efficiency.

- Client: An Cuong Building Materials

- Objective: Maintain stable humidity levels in the production facility, protect tile press systems from rust and wear, and ensure the quality of tile powder is not affected by moisture.

- Installation: Kosmen KM-250S industrial dehumidifier

- Location: Lot CN11+CN12, An Đong Industrial Cluster, Nam Sach Town, Nam Sach District, Hai Duong Province, Vietnam

Benefits of Using Kosmen Dehumidifiers

- Effective humidity control – Protects press systems, reduces the risk of rust, and extends equipment lifespan.

- Prevents material degradation – Keeps tile powder from clumping or deteriorating, ensuring strong adhesion, a smooth surface, and minimal defects in the final product.

- Reduces maintenance costs – Lowers expenses for machine repairs and upkeep, helping businesses save on operational budgets.

- Enhances production efficiency – Ensures smooth, uninterrupted operations by preventing equipment failures.

- Improves the working environment – Keeps the facility dry and clean, creating optimal conditions for machine operators.

Business Review

After integrating Kosmen dehumidifiers into the production system, An Cuong Building Materials has noticed a significant improvement in humidity control. The press machines operate more smoothly, the defect rate in products has decreased considerably, and overall production efficiency and tile quality have improved. Additionally, the company highly values the energy efficiency and durability of Kosmen dehumidifiers, which help optimize long-term operating costs.

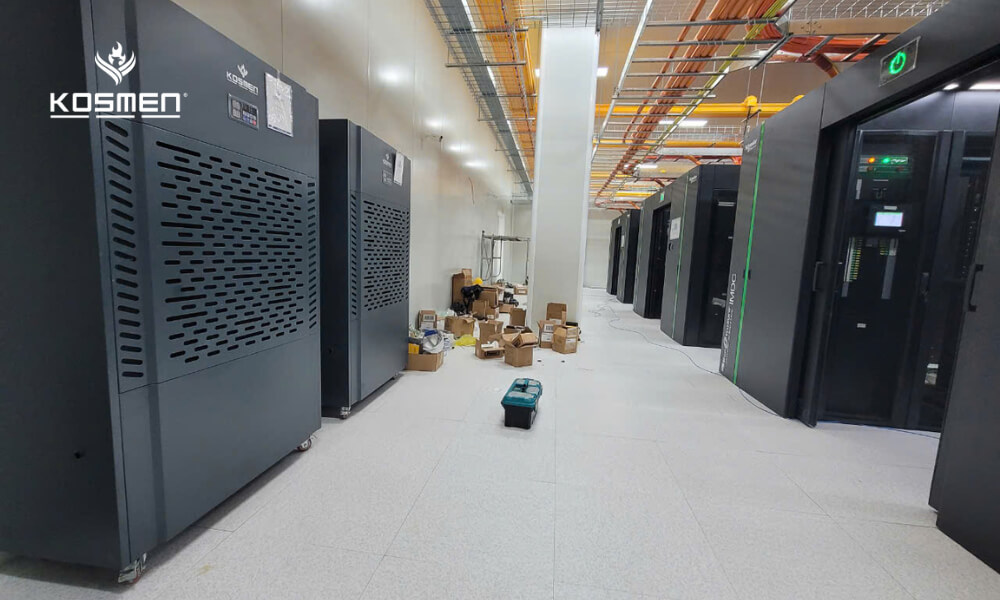

Below are real-life images of the Kosmen dehumidifier system in use at An Cuong Building Materials’ artificial ceramic tile production process:

The Kosmen KM-250S dehumidifier protects press machines from rust and damage, extending their lifespan

The Kosmen KM-250S dehumidifier protects press machines from rust and damage, extending their lifespan  With a dehumidification capacity of 250 liters per day, the Kosmen KM-250S ensures a consistently dry production environment for ceramic tiles

With a dehumidification capacity of 250 liters per day, the Kosmen KM-250S ensures a consistently dry production environment for ceramic tiles  Its intelligent design and advanced features optimize the manufacturing process

Its intelligent design and advanced features optimize the manufacturing process  An Cuong Building Materials – a specialized artificial ceramic tile manufacturing plant

An Cuong Building Materials – a specialized artificial ceramic tile manufacturing plant