Published:30.09.2025

See moreDehumidifier for Humidity Control in Vaccine Production

Published:

07/01/2026, 09:26

- Updated at 07/01/2026, 09:39

Published:

07/01/2026, 09:26

- Updated at 07/01/2026, 09:39In the vaccine manufacturing industry, air humidity is a critical factor that directly affects product quality, stability, and safety. When humidity exceeds permissible levels, the risks of condensation, raw material moisture absorption, reduced biological activity, and disruption of sterile environments become unavoidable. This not only interrupts production processes but also poses significant risks to quality control and compliance with strict GMP standards.

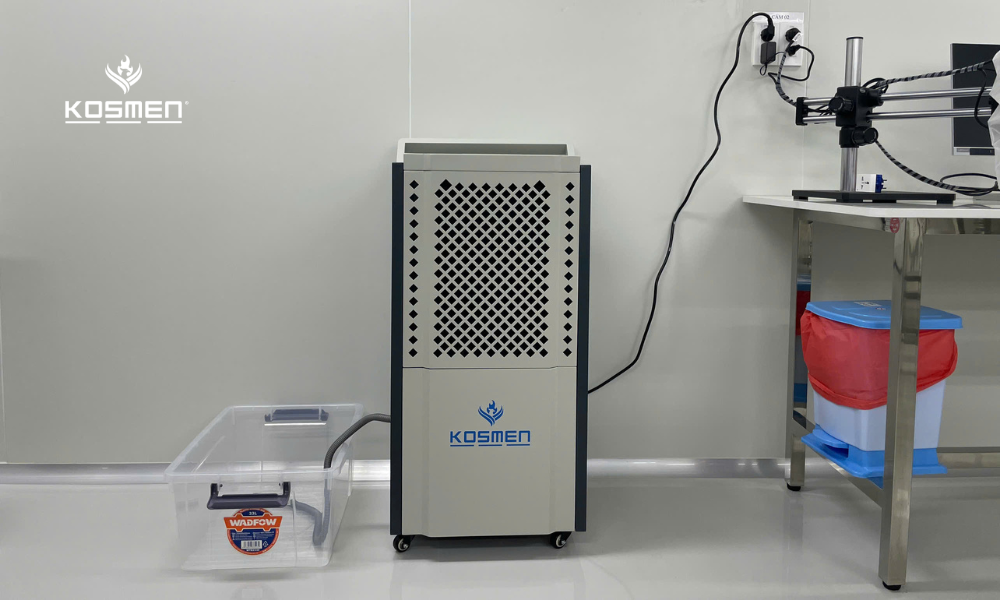

To ensure stable humidity control in the production area, Vaccine of Da Lat Pasteur Limited Company selected Kosmen industrial dehumidifier solutions. The system was installed to maintain a dry, clean, and compliant air environment, ensuring optimal conditions for vaccine formulation, packaging, and storage.

Project information

- Customer: Vaccine of Da Lat Pasteur Limited Company

- Location: No. 18 Le Hong Phong Street, Xuan Huong Ward – Da Lat City, Lam Dong Province, Vietnam

- Equipment Used: Kosmen KM-90S Industrial Dehumidifier

- Objective: Maintain stable humidity levels, ensure GMP-compliant production environments, and preserve vaccine quality.

Benefits after installation

After the Kosmen dehumidification system was put into operation, the vaccine production area maintained stable humidity within standard limits, delivering clear benefits:

- No condensation observed in vaccine production and packaging areas.

- Raw materials, semi-finished products, and finished vaccines are stored in a dry and safe environment.

- Reduced risk of moisture-related contamination and cross-contamination, supporting vaccine quality and stability.

- Clean, well-ventilated production spaces that meet strict hygiene and sterility requirements.

- Stable, quiet operation with energy efficiency, suitable for continuous production.

Customer feedback

Previously, during periods of high ambient humidity, the vaccine production area faced significant challenges in maintaining stable environmental conditions. This affected quality control efforts and increased potential risks during manufacturing.

After installing the Kosmen industrial dehumidification system, humidity levels in the factory are now tightly controlled, fully meeting the stringent requirements of the pharmaceutical and biotechnology sectors. The company highly values the system’s powerful dehumidification performance, durable and stable operation, and long-term energy-saving benefits—contributing to improved production efficiency and consistent vaccine quality.

Below are some images from the project:

The Kosmen KM-90S dehumidifier creates a clean environment and ensures standard-compliant conditions for vaccine production

It operates stably, quietly, and energy-efficiently, making it suitable for continuous manufacturing processes

The Kosmen KM-90S helps prevent moisture-related issues and cross-contamination, protecting the quality of both raw materials and finished vaccines