Optimal Moisture Control Solutions For The Printing And Decal Industry

Published:

25/03/2025, 16:34

- Updated at 30/09/2025, 16:01

Published:

25/03/2025, 16:34

- Updated at 30/09/2025, 16:01In the printing and decal industry, humidity is one of the most critical factors affecting the quality of the final product. Maintaining optimal humidity levels not only ensures the stability of printing materials but also enhances the efficiency of machinery and equipment in the production environment.

The importance of humidity control in the printing and decal industry

Just like in other industries, managing and maintaining standard humidity levels is a crucial aspect of the printing and decal sector. Each material and product has specific requirements during the printing process. For ceramic printing, maintaining safe humidity levels helps ensure vibrant and durable colors without blurring, smudging, or fading.

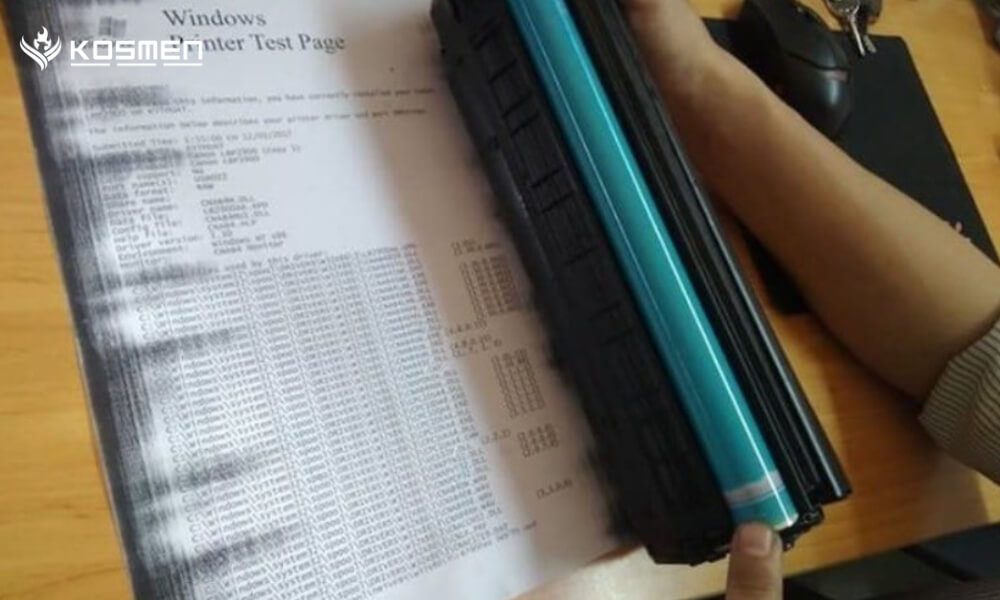

Ink on printed products can become blurred or smudged due to humidity

For paper printing, standard humidity control prevents mold growth caused by moisture penetration. It also facilitates smoother printing operations, reducing the risk of information loss due to humidity fluctuations. In the textile printing industry, controlling humidity ensures that ink adheres firmly and displays accurate colors while also preventing fabric materials from becoming moldy, damp, or developing unpleasant odors.

Each material demands appropriate humidity maintenance based on its unique characteristics. Therefore, every stage of production and storage must carefully consider ideal humidity levels. Additionally, manufacturing facilities should be equipped with specialized humidity control devices to ensure the highest product quality.

How humidity affects the printing and decal industry

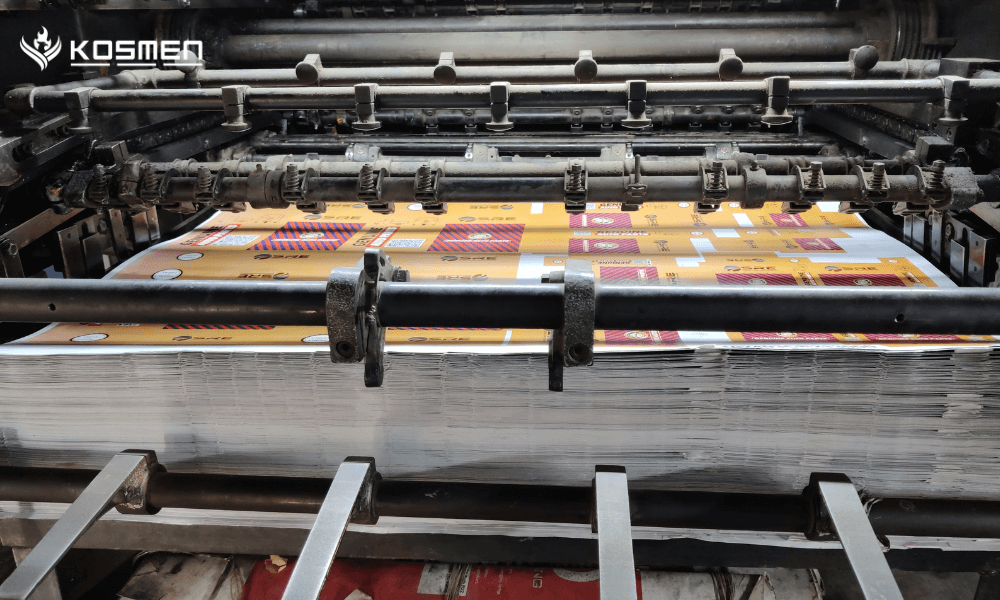

In printing production, several factors directly impact the durability and color quality of printed materials, with air humidity being the most influential element.

Effects of humidity on various printing materials:

- For printing paper: Paper is soft, thin, and highly absorbent, making it susceptible to warping, wrinkling, and mold in high humidity conditions. Excessive moisture not only fosters mold growth but also worsens contamination, potentially damaging large quantities of raw materials and finished products. On the other hand, low humidity levels can cause static electricity, attracting dust to paper and machinery, disrupting the printing process.

- For printing ink: High humidity can cause ink to blur, smudge, or run, leading to printing errors and potential loss of critical information. Conversely, extremely low humidity does not cause mold but can make paper brittle and less absorbent, negatively impacting ink adhesion.

Humidity reduces ink absorption, making it harder for ink to adhere to the product

- For ceramic products: Low humidity in ceramic printing environments can lead to cracks or breakage, reducing product longevity and altering the final printed design. Conversely, high humidity levels may prevent ink from adhering evenly to the ceramic surface, resulting in smudged or faded prints.

- For fabric materials: High humidity in textile printing often leads to mold stains, reducing fabric aesthetics. Excess moisture can also cause fabric jams in printing machines, damaging equipment and slowing production. Additionally, excessive humidity affects ink adherence, causing colors to fade, smudge, or peel after washing.

- For canvas, leather, plastic, and synthetic materials: These materials are also highly susceptible to mold growth if exposed to high humidity. Without proper humidity control from the initial stages of production, they can deteriorate and require costly replacements.

Most printing materials can be damaged by humidity

Beyond affecting materials, humidity can also damage printing machinery and disrupt production processes:

- Impact on printing plates: When removed from the mold, films or paper may generate static electricity if the air humidity is below 40%, attracting dust and complicating the printing process. In severe cases, this static charge could even create sparks, posing safety risks.

- Effects on digital printing: Digital printing processes involve complex machinery, making humidity control essential. High humidity can cause static electricity issues, short circuits, and decreased operational efficiency, impacting overall print quality.

Low humidity can cause static buildup on printing plates

Besides material and production concerns, excessive humidity prolongs drying times for printed products, creating an environment conducive to mold growth and reducing product durability. Some printed items require post-print drying to enhance ink adhesion and color quality. However, excessive moisture can extend drying times, lowering productivity and affecting final product quality.

For decal printing, harsh environmental conditions can lead to peeling. While many decals are designed to be water-resistant and durable, lower-quality products may become blurry or heavily damaged in high humidity environments.

Decal easily peels off and loses adhesion if storage humidity is high

Ideal humidity levels for the printing and decal industry

To ensure smooth printing operations, maintaining humidity levels between 45% and 60% is optimal for preserving machinery, equipment, and product quality. However, each material has specific humidity requirements. Manufacturers can refer to the following general guidelines to maintain appropriate moisture levels in their production lines:

| Product | Standard Humidity |

| Ceramic products | 50% |

| Paintings, leather, plastic, simili | 50 - 60% |

| Fabrics | 40 - 60% |

| Printing paper | 40 - 60% |

Humidity levels fluctuate with seasonal changes, often reaching saturation during the rainy or humid seasons. To effectively manage excessive moisture in storage and production areas, businesses should invest in humidity control devices that allow quick adjustments, ensuring ideal conditions while also supporting the drying process. This approach optimizes production efficiency while reducing maintenance and repair costs for machinery.

Optimal moisture control solutions for the printing and decal industry

To maintain safe humidity levels throughout the production process, businesses should prioritize dehumidifiers as specialized moisture control solutions. These devices remove excess humidity from the air, ensuring a dry environment that meets industry standards.

Key benefits of using industrial dehumidifiers in printing and decal production:

- Prevents raw materials from mold and moisture damage

- Ensures paper, printing materials, and ink remain unaffected by humidity

- Keeps printed products free from moisture retention, preserving sharp details and vibrant colors

- Reduces ink clogging issues, improving machinery efficiency

- Protects machinery from rust and electrical malfunctions

- Maintains a clean, dry, and safe workspace.

Enhances workplace conditions, promoting better employee health

Kosmen industrial dehumidifiers are an ideal choice for businesses in the printing and decal industry. With capacities ranging from 90 to 480 liters per day, users can easily select the right device to match their production environment and moisture control requirements.

Kosmen industrial dehumidifiers are applied in the printing and decal industry

Beyond humidity control, Kosmen’s industrial dehumidifiers come equipped with drying functions that help shorten drying times for printed products, preventing moisture retention. Additional advanced features include: Timer settings, adjustable humidity control, work history memory, automatic defrosting, overload protection, WiFi connectivity for remote control via mobile apps

Top 5 Kosmen dehumidifiers recommended for printing businesses:

| Model | Dehumidification Capacity | Dehumidification Range |

| Kosmen KM-90S Industrial Dehumidifier | 90 liters/day | 90 - 120m2 |

| Kosmen KM-150S Industrial Dehumidifier | 150 liters/day | 120 - 200m2 |

| Kosmen KM-180S Industrial Dehumidifier | 180 liters/day | 200 - 250m2 |

| Kosmen KM-250S Industrial Dehumidifier | 250 liters/day | 400 - 550m2 |

| Kosmen KM-480S Industrial Dehumidifier | 480 liters/day | 600 - 800m2 |

The above insights highlight the impact of humidity on the printing and decal industry and provide recommendations for effective moisture control solutions. If you are looking to purchase an industrial dehumidifier or need expert consultation on tailored humidity control solutions, contact Kosmen Vietnam today for prompt assistance and guidance!

KOSMEN - GERMAN BRAND

- Head Office: 27B Street 12, KP2, Hiep Binh Phuoc Ward, Thu Duc City

- Hanoi Office: NV 4.7, Hai Au 2 Street, Cau Buou Urban Area, Thanh Tri, Hanoi

- Da Nang Office: 385B Hai Phong Street, Tan Chinh Ward, Thanh Khe District, Da Nang

- Da Lat Office: 1A Hoang Van Thu Street, Ward 4, Da Lat City, Lam Dong Province

- Hotline: 0766 899 799 (North) - 0888 787 959 (South) - 0961 061 076 (Central Highlands)

- Website: kosmen.com.vn