Published: 18.12.2024

See moreThe Impact of Humidity in Automotive Glass Manufacturing

Published:

25/03/2025, 11:56

- Updated at 30/09/2025, 15:45

Published:

25/03/2025, 11:56

- Updated at 30/09/2025, 15:45Maintaining optimal humidity levels in manufacturing workshops and storage warehouses is crucial for long-term operations, and the automotive glass industry is no exception. Implementing specialized solutions in this field, such as dehumidifiers, is the perfect choice to ensure efficiency.

How does humidity affect the automotive glass manufacturing process?

As in many other manufacturing sectors, humidity control is considered one of the most critical steps to ensure that automotive glass products meet required quality standards.

Impact on the durability of laminated glass adhesive

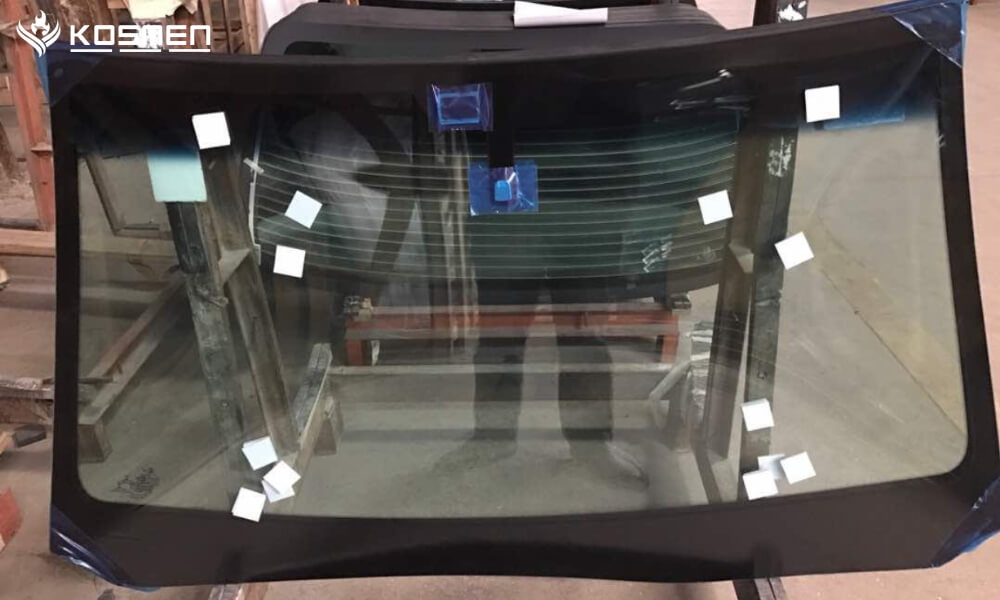

Safety glass is commonly used in vehicles such as cars, trucks, and buses. The PVB (Polyvinyl Butyral) interlayer adhesive plays a vital role in bonding two layers of glass together. Generally, glass materials are highly water-resistant.

Adhesive for automotive glass can be damaged and lose adhesion if exposed to moisture

However, in laminated glass, if the interlayer adhesive is exposed to excessive humidity, it can become compromised. Unlike glass, PVB adhesive is highly moisture-absorbent. If humidity levels are too high during production, the adhesive can delaminate, reducing adhesion quality and compromising product safety.

Impact on glass cutting materials

High humidity does not only affect glass quality but also impacts the machinery and tools used for glass cutting. Excess moisture can degrade the performance of grinding and cutting tools, especially those made of metal, as these materials are prone to rust when exposed to humidity.

Impact on the manufacturing environment

Prolonged exposure to high humidity levels in workshops can lead to severe mold growth, damaging machinery, reducing aesthetic appeal, and compromising the quality of the facility. Additionally, increased humidity and mold growth can negatively impact workers' health.

Glass cutting materials can oxidize if the environment is too humid

Optimal humidity levels for automotive glass manufacturing

To protect raw materials and machinery from damage, manufacturing facilities should maintain humidity levels within standard thresholds. In automotive glass production, the ideal humidity range is between 43% and 60%.

In countries with a tropical monsoon climate and high year-round humidity, such as Vietnam, controlling humidity is not just about product preservation—it is also an optimal solution to minimize environmental impact.

Standard humidity must be maintained throughout automotive glass production

To maintain stable humidity levels, businesses should invest in specialized equipment such as dehumidifiers. These devices regulate and balance humidity according to industry standards, ensuring smooth production and storage while minimizing humidity-related risks.

Humidity control solutions for automotive glass manufacturing using dehumidifiers

Dehumidifiers are specialized equipment designed to provide the most effective humidity control solutions available today. With their primary function of absorbing moisture and maintaining standard humidity levels, these devices help keep manufacturing and storage spaces dry and clean.

Key benefits of using dehumidifiers in automotive glass production:

- Removes excess moisture from the air to maintain an ideal humidity balance in the production environment

- Prevents moisture infiltration, reducing the risk of air bubbles forming

- Protects PVB adhesive from humidity exposure, maintaining strong adhesion

- Prevents the growth and spread of dust and mold

- Ensures a dry, clean workspace

- Supports workers' health and well-being.

Kosmen dehumidifiers offer an intelligent solution that meets all these requirements. Kosmen is a renowned brand specializing in industrial dehumidifiers, featuring German humidity control technology. With a diverse range of capacities and models, Kosmen's products cater to various needs, from small-scale home use to large warehouses and industrial production facilities.

For automotive glass manufacturing, businesses can explore Kosmen's industrial dehumidifier series, which offers capacities ranging from 90 to 480 liters per day. Users can easily select the most suitable model based on their workspace size and specific humidity control requirements.

Kosmen industrial dehumidifiers are applied in automotive glass production lines

In addition to dehumidification, Kosmen's humidity control models include advanced features such as adjustable humidity settings, continuous drying mode, WiFi connectivity, automatic defrosting, and overload protection. The WiFi connectivity function allows users to manage and adjust settings remotely, eliminating the need for manual operation in the workshop. Additionally, through the app, users can schedule operations and monitor real-time environmental humidity levels.

Below are some of the most trusted Kosmen industrial dehumidifier models widely used by businesses today:

| Model | Dehumidification Capacity | Dehumidification Range |

| Kosmen KM-90S Industrial Dehumidifier | 90 liters/day | 90 - 120m2 |

| Kosmen KM-150S Industrial Dehumidifier | 150 liters/day | 120 - 200m2 |

| Kosmen KM-180S Industrial Dehumidifier | 180 liters/day | 200 - 250m2 |

| Kosmen KM-250S Industrial Dehumidifier | 250 liters/day | 400 - 550m2 |

| Kosmen KM-480S Industrial Dehumidifier | 480 liters/day | 600 - 800m2 |

For production spaces with numerous shelves, machinery, or limited floor space, businesses can also consider Kosmen’s ceiling-mounted dehumidifiers. With a capacity range from 66 to 480 liters per day, these units effectively manage humidity across various production environments. A key advantage of ceiling-mounted dehumidifiers is their installation at elevated positions, saving space while ensuring better air circulation.

Like Kosmen’s upright dehumidifiers, the ceiling-mounted models also include intelligent features such as humidity control, continuous drying mode, timer settings, work history memory, automatic defrosting, and overload protection. Specifically, the Kosmen KM-66E and Kosmen KM-180DS models feature WiFi connectivity, enabling remote control and operation adjustments.

Below is a summary of Kosmen’s top ceiling-mounted dehumidifier models for businesses to consider:

| Model | Dehumidification Capacity | Dehumidification Range |

| Kosmen KM-66E Ceiling-Mounted Dehumidifier | 66 liters/day | 60 - 80m2 |

| Kosmen KM-168DS Ceiling-Mounted Dehumidifier | 168 liters/day | 100 - 200m2 |

| Kosmen KM-180DS Ceiling-Mounted Dehumidifier | 180 liters/day | 200 - 250m2 |

| Kosmen KM-240DS Ceiling-Mounted Dehumidifier | 240 liters/day | 300 - 380m2 |

| Kosmen KM-480DS Ceiling-Mounted Dehumidifier | 480 liters/day | 400 - 700m2 |

Currently, Kosmen’s branch and dealership network spans all provinces and cities nationwide. Customers and businesses looking to purchase Kosmen dehumidifiers can easily explore products at official distribution outlets or contact the hotline for expert consultation on the most suitable solutions tailored to industry standards.

Contact information

- Head office: No. 27B Street 12,Hiep Binh Phuoc Ward, Thu Duc city, Ho Chi Minh City

- Ha Noi Branch: No. NV 4.7 Hai Au 2 Street, Cau Buu Urban Area, Thanh Tri District, Ha Noi City

- Da Nang Branch: No. 385B Hai Phong Street, Tan Chinh Ward, Thanh Khe District, Da Nang City

- Da Lat Branch: No. 1A Hoang Van Thu Street, Ward 4, Da Lat City

- Hotline: 0766 899 799 (North) - 0888 787 959 (Southern) - 0961 061 076 (Central Highlands)

- Website: https://kosmen.com.vn/